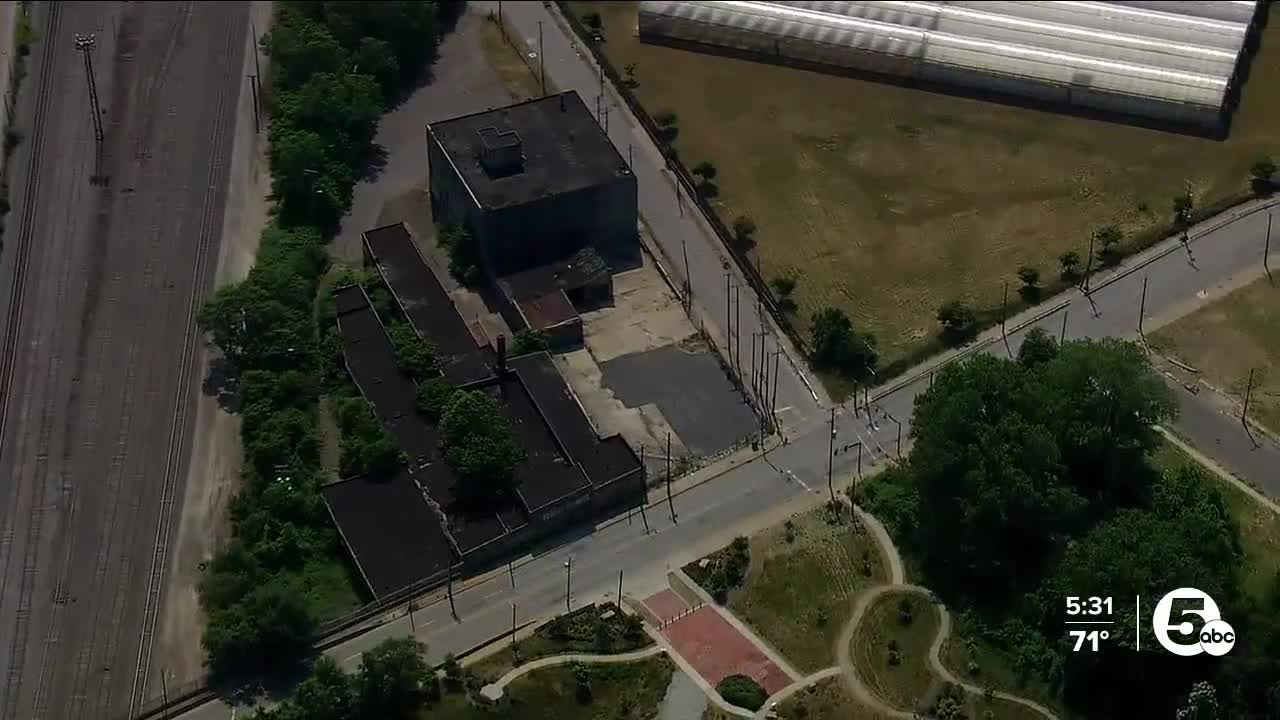

CLEVELAND — An extensive, nearly $2 million cleanup of a long contaminated industrial site on Cleveland’s East side was recently completed, moving the decrepit vestige of the city’s industrial past one step closer to a more productive future.

Once a sprawling, block-wide electroplating and chrome plating facility at Grand and Kinsman avenues, Diamond Hard Chrome began dying on the vine following a large fire that gutted the operation on Jan. 13, 1991. The fire-singed brick frame of the main production facility was eventually demolished. The contaminated debris was later buried and placed under a protective cap, preventing seepage into the nearby environment. Although the business continued to operate for more than a decade after the fire at an adjoining building, the company later ceased operations, essentially wiping its hands clean of the voluminous amount of hazardous sludge, liquid and debris still present at the building.

The primary hazard at the site was hexavalent chromium, which is widely used in electroplating, stainless steel production and wood preservation. Diamond Hard Chrome’s operation includes chrome and electroplating services for steel rolls and shafts used by the steel and printing industries, according to EPA records.

What followed the business’ closure was a time-critical cleanup operation conducted by the U.S. Environmental Protection Agency and an environmental contractor. EPA on-scene coordinator, Eric Pohl, said the operation involved the removal of more than 200 tons of solid waste and high-hazard solid waste. As many as 10,000 gallons of liquid waste were also removed and transported to a hazardous material disposal facility.

“Essentially, rainwater seeped through the broken ceiling and roof of the facility,” Pohl said as he pointed to a 2022 photo showing a murky, yellowish-green pond of liquid on the basement floor. “It’s now coming into contact with the residual contamination, and that’s all hexavalent chromium. This is just one puddle of stuff that was spilled out. Essentially, the entire interior of the building is just covered in this chromium in the walls, flooring and the ceiling.”

Over the past year, Pohl and other remediation specialists painstakingly removed the contaminated material, sludge and liquid waste. Hexavalent chromium, like other heavy metals, is a known carcinogen.

“We were notified that the owners of the site were preparing to shut down their operation and walk away from it,” said EPA Region 5 Administrator Debra Shore. “Somebody needed to be there to make sure it didn’t pose a significant threat to the community. Hexavalent Chromium, lead, and other heavy metal contamination posed a critical threat to the communities and ecosystems that neighbor this site.”

Although the EPA can seek to recoup the costs of remediation through legal channels, such attempts often prove fruitless due to the fact that bankrupt limited liability companies often have little to no assets to claw back. The remediation of the Diamond Hard Chrome site was funded entirely through the EPA.

“We will attempt to do that in this case, but I don't [know] how successful we will be,” Shore said.

The remediation of the site greatly improves the long-term prospects for future industrial, commercial and manufacturing-related redevelopment at the site.

Using part of the city’s tranche of American Rescue Plan Act dollars, Mayor Justin Bibb has made the redeveloping of Brownfields and other industrial sites on the East Side one of his core policy priorities.

“Redeveloping this part of the city is a major priority of our administration,” Bibb said. “[I see] opportunity. That’s why we are so excited about our $50 million site fund to redevelop over 1000 acres of vacant land because we believe those sites can be put to good, productive use to attract and retain new companies so our residents can have jobs in their neighborhood.”

Bibb said his site development plan is centered around cobbling together large tracts of publicly-controllable land and making the sites ‘shovel-ready’ for development.

“Sites that are large scale — that are 20, 30, 40 acres of land — because that’s what we’re hearing from companies right now,” Bibb said. “They need those large sites, particularly in advanced manufacturing, healthcare and IT, to really bring jobs back to our city.”